CTU Testbed for Industry 4.0 at CIIRC CTU

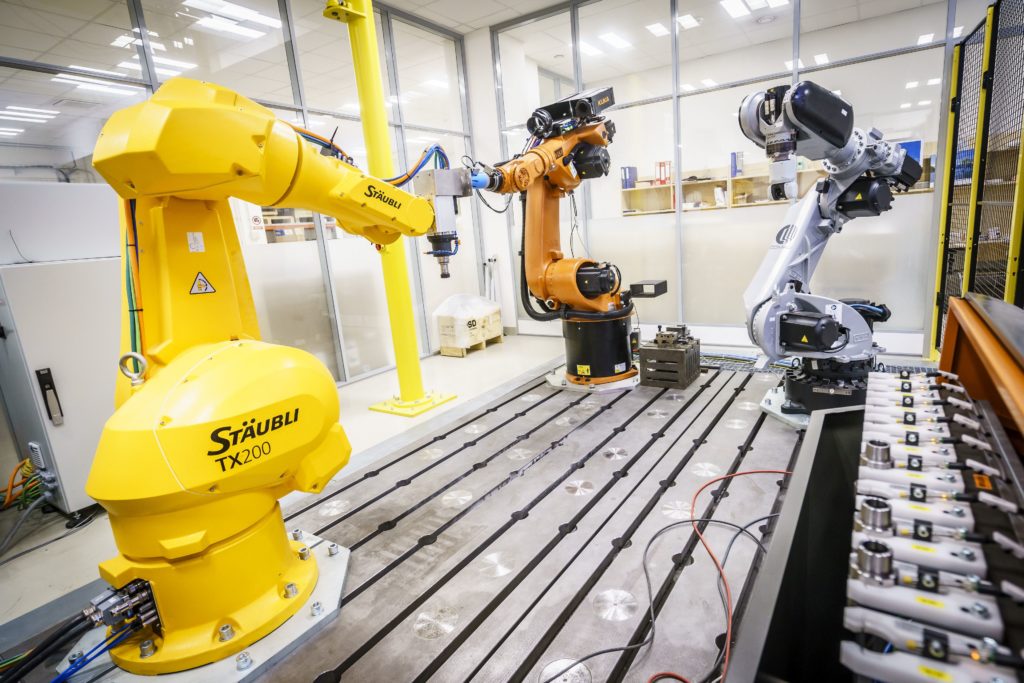

The Testbed for Industry 4.0 at CIIRC CTU as an integral part of RICAIP and as a research and experimental workplace is the core asset for the exploitation of results of multiple research projects. The Testbed is a unique research facility for the development and testing of innovative solutions for advanced and fully integrated industrial production and processes for smart factories.

The two specifically focused floors of the testbed together create a completely unique environment for testing, simulation and development of various scenarios for smart factories of the 21st century. The lower floor of the testbed in the basement is focused on production technologies and production machines, while one floor above there are modules designed for flexible production. The latest technologies are designed for research and development of applications for industrial practice. Universal robotic and production cells, including collaborative robots and machine tools, are intra-logistically interconnected by a fleet of mobile robots and vehicles; by software and data also at the level of the so-called edge equipment and through server and cloud applications using artificial intelligence algorithms. The testbed enables experimentation with available devices or the connecting of new devices. Thanks to the versatility of production elements and the control system, the same resources can be used and optimized to perform different operations.

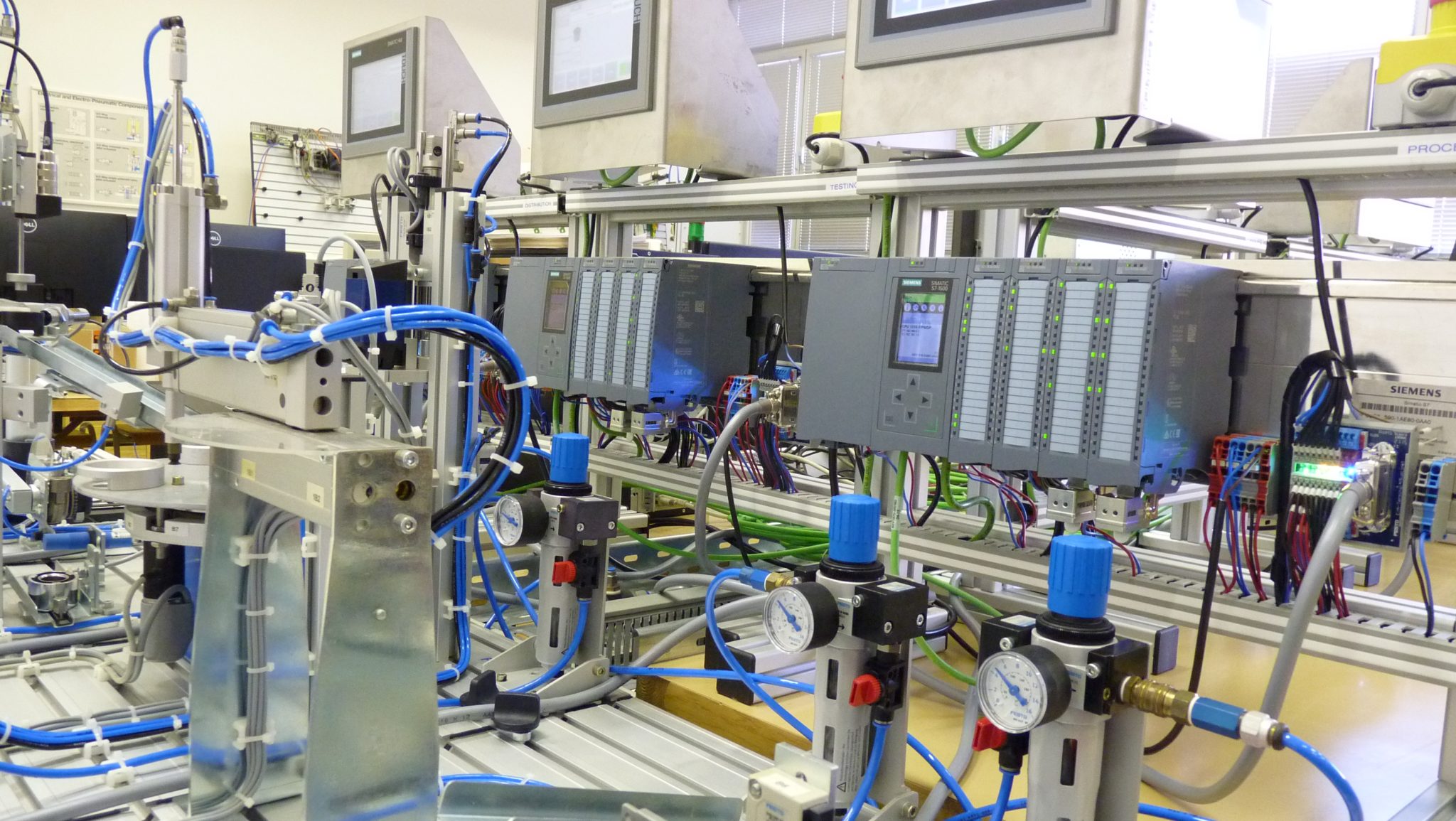

STUBA Learning Factory for Industry 4.0

The STUBA LF is focused on shop-floor digitalization and undergoes adaptation of its technical infrastructure towards the I4.0 concept. This includes machinery retrofits, installation of sensors for quality inspection and process monitoring purposes, use of digital twin techniques for process performance optimization and machine diagnostics, integration of condition monitoring and predictive maintenance methods, as well as data processing and evaluation in cloud.

More information can be found HERE.

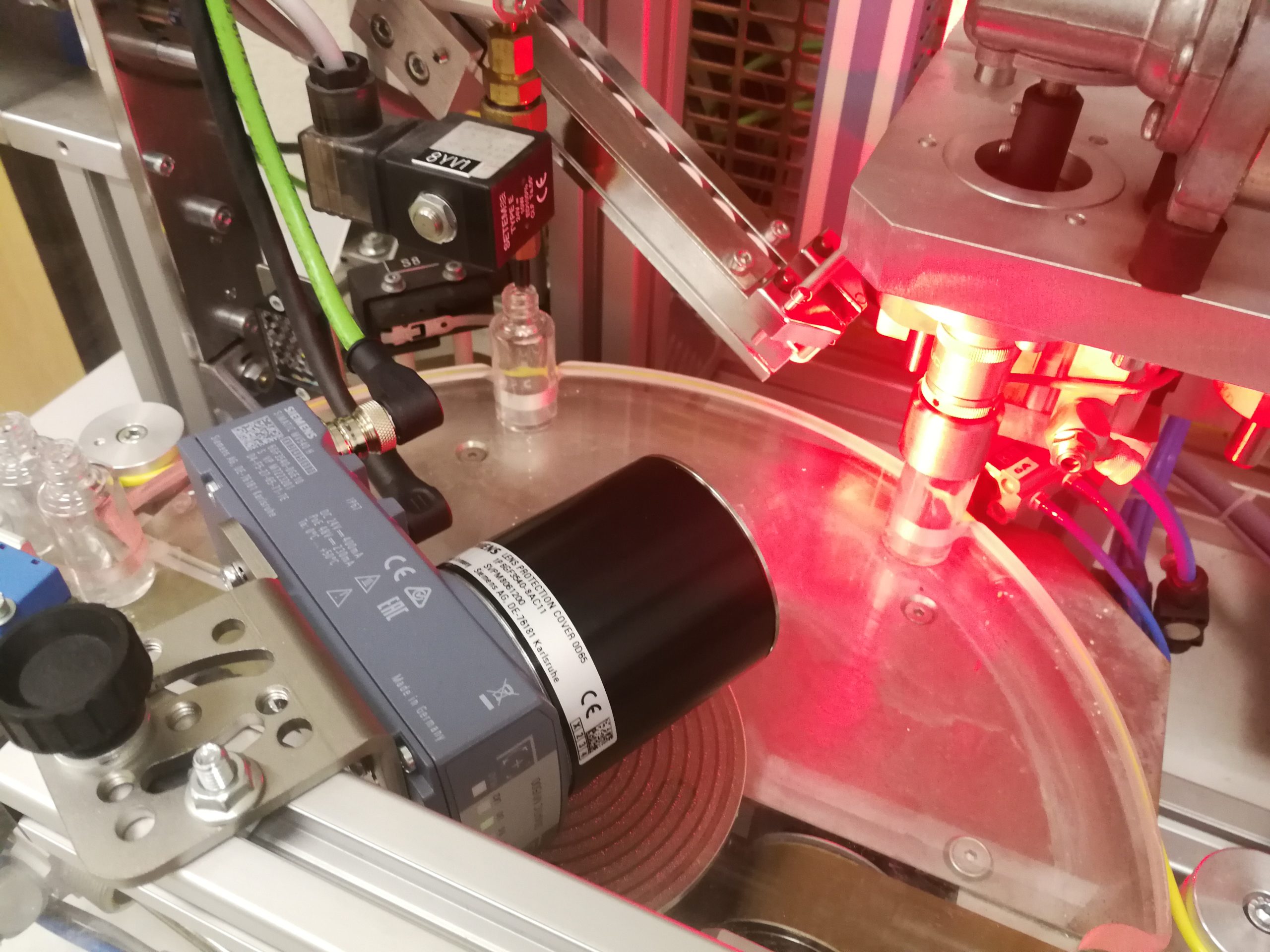

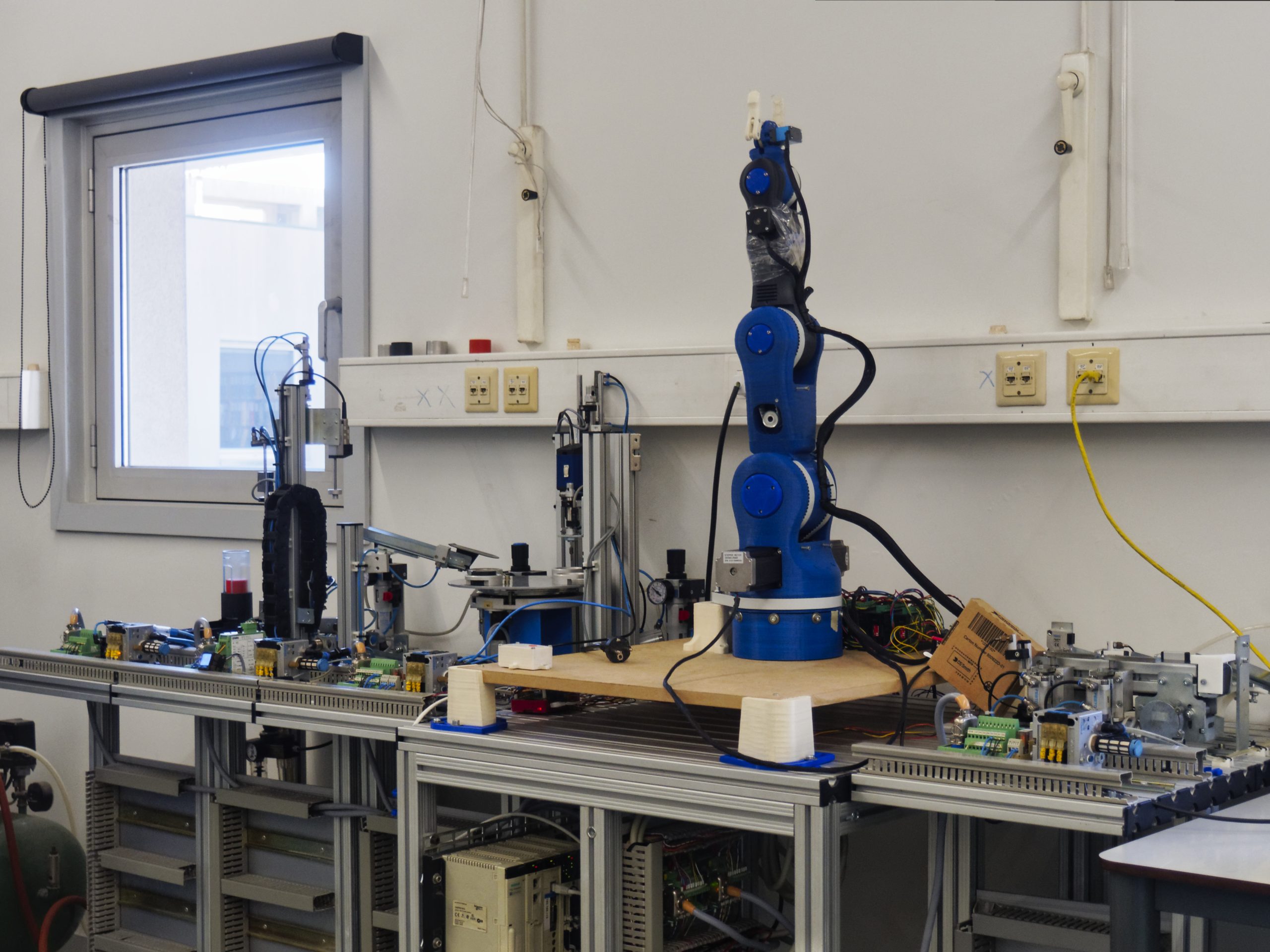

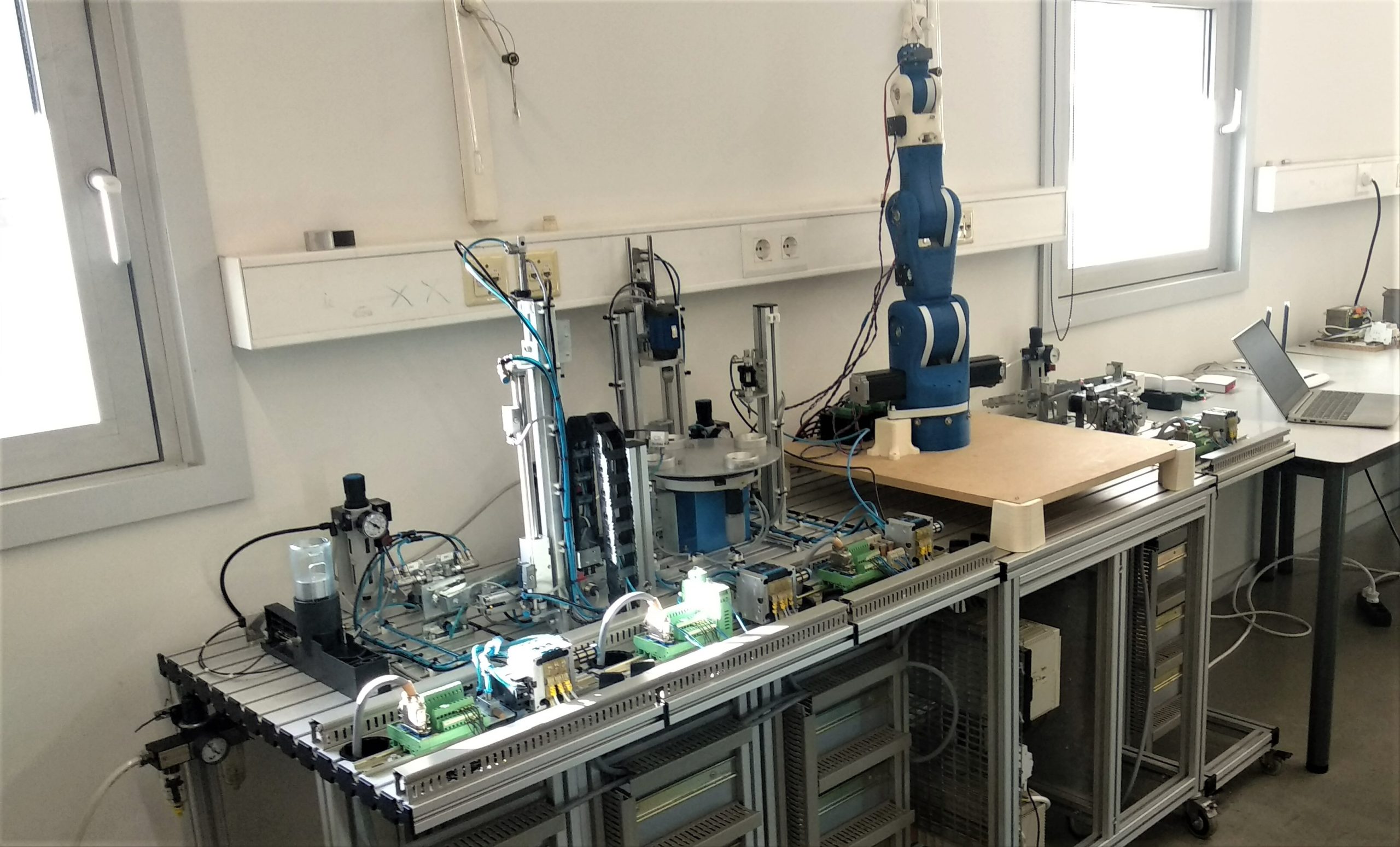

FEUP Learning Factory for Intelligent Manufacturing

Sustainability alongside efficiency constitutes a top priority for the industry nowadays. The transition to the fourth industrial revolution brings with it a modernization of the shop floor. This modernization can sometimes be misleading in the way it is implemented, leading to the disposal of old but functional assets. In FEUP, the concepts of industrial refurbishment and retrofitting are explored in the implementation of a learning factory. While the repurposing itself is an important lesson, a set of three additional learning nuggets was created. These nuggets explore the topics of Zero Defects, Condition Monitoring and System Integration. An IEC 61499 runtime environment capable of running Python function blocks was integrated with the learning factory. This technology allows for the hands-on exploration of these and other topics, on-site or remotely. By combining the refurbishment strategy with these technological topics, this learning factory is a demonstrator of how the Industry 4.0 revolution can have sustainability at the centre.

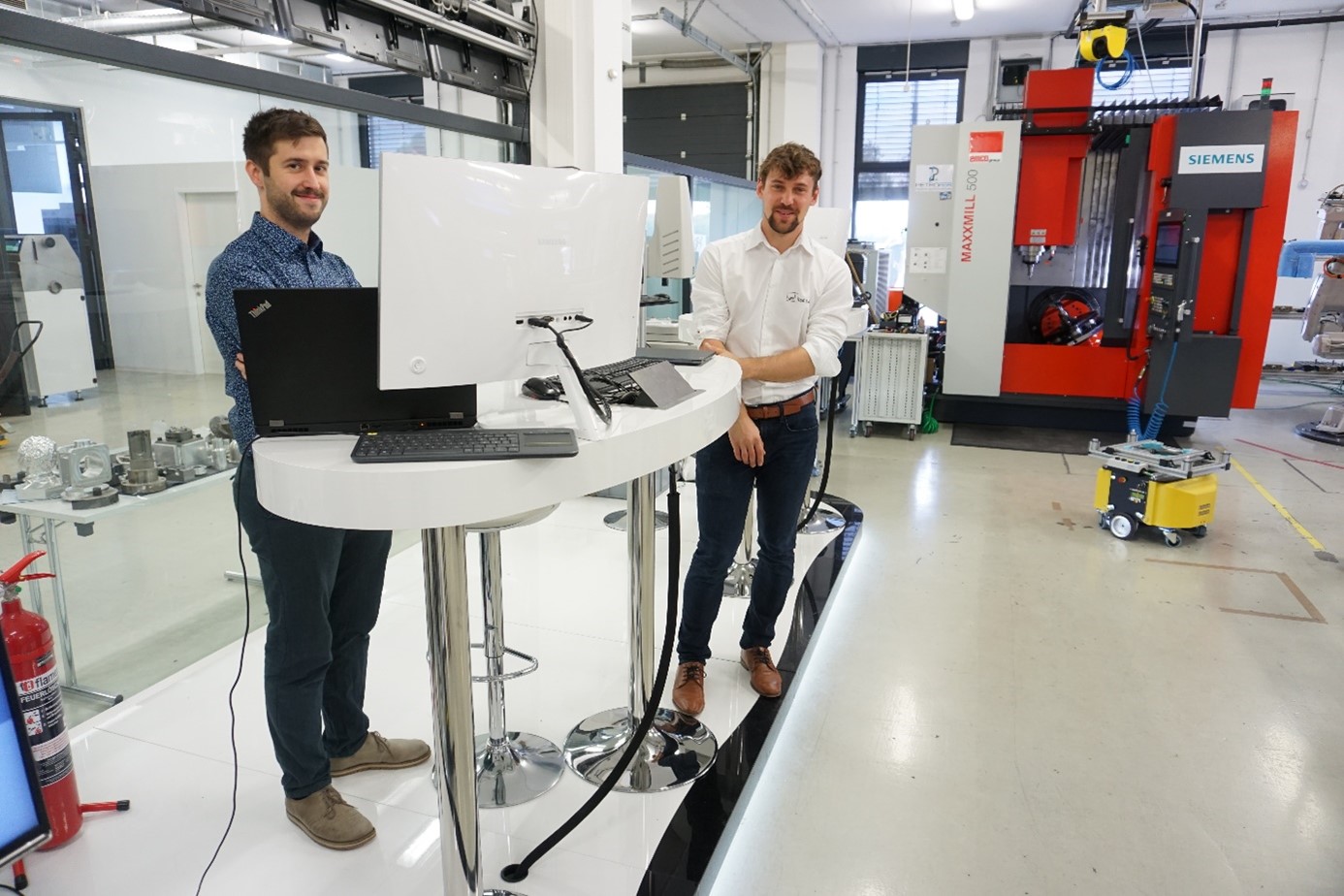

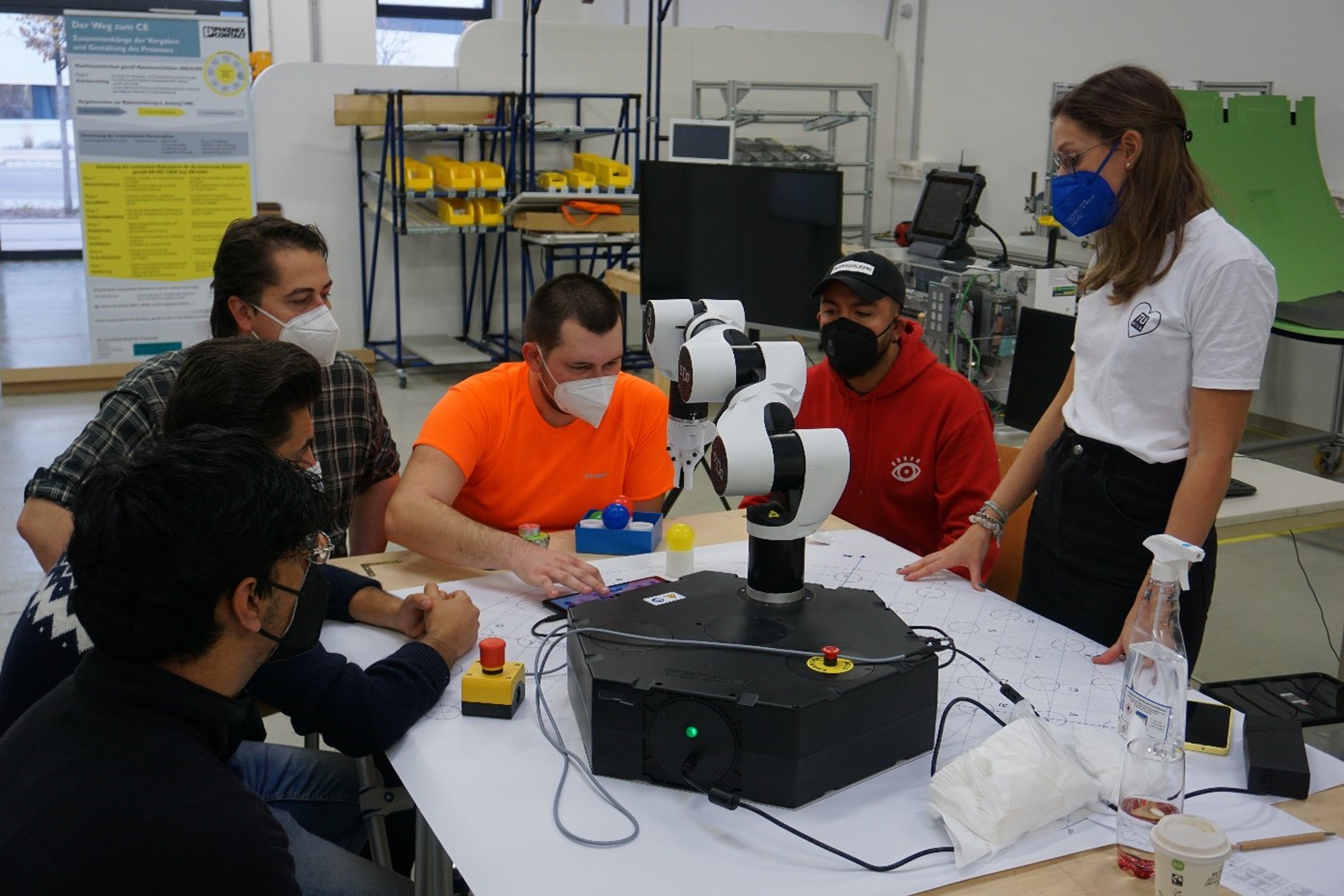

TU Wien Pilot Factory Industry 4.0

The TU Wien Pilot Factory Industry 4.0, as learning, innovation and demonstration factory for smart production and cyber-physical production systems, focuses on new concepts and solutions for a multi-variant serial production in the field of discrete manufacturing industry, which are typical for many Austrian companies. On approx. 900 m², the creation of a 3D printer is shown from the design to the production and assembly of the mechanical part to the shipping to the end customer. In the production area, robot-supported flexible manufacturing cells were combined with industrial robots. The realization of “Machine to Machine Communication” of these systems, which come from different manufacturers, was implemented. At the same time, an assembly and logistics landscape was also created in the pilot factory, in which human employees are the focus. They are assisted and supported in their work by the latest Industry 4.0 technologies, such as various visual and digital assistance systems and by collaborative robots.

More information can be found HERE.

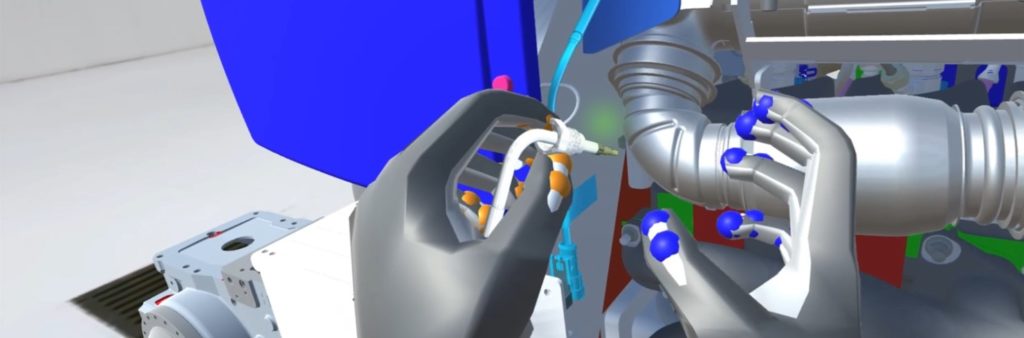

UNIMORE Learning Factory about Human-Centered Virtual Manufacturing

The UNIMORE LF is focused on the adoption of Virtual Reality and Augmented Reality / Mixed Reality technologies to promote the human-centered virtual manufacturing. Digital simulation allows to design and validate industrial systems, processes, and interfaces, by focusing on the human needs and expectation. Contemporarily, digital tools are also used to create immersive and interactive learning environments for training operators and technicians, in a faster and more efficient way, thanks to a “learn-by-doing” approach. Indeed, VR-based training is a good way to move the practical experience taken from real factories at a digital level, used in combination to traditional training methods.

The final aim is to synergically develop human-centered industrial workstations, guaranteeing both the operators’ wellbeing and the highest process performance, and to enhance a new, fruitful dialogue between humans and machines into the modern factories.